Whatsapp//Wechat: 86-13427954596

Facebook:

www.facebook.com/li.karen.184881

Email:

karen@kyd-esd.com

sales@kyd-esd.com

sales001@kyd-esd.com

The plastic film layers are a kind of proprietary polyethylene film which is produced via high-pressure technology. This method eliminates the use of heavy metal catalysts and no measurable amounts of cadmium,chlorine,sodium or lead are present in the film. Also the pressure sensitive adhesive is acrylic based and is free of any metal cross-linking agents. The top and bottom release films are also polyethylene films and contain no release coatings.

KYD sticky mats typically come in 30 or 60 sheets per pad and have corner tabs that are consecutively numbered to show the number of remaining sheets. Also KYD’s sticky mats have a specially developed adhesive coating designed to provide an effective means of reducing dirt by trapping and preventing the transfer of particles.

1.Smooth and durablestrong sticky dust

It is composed of multiple layersof polyethylene film,each layer isattached with a high-viscositycoating,non-degumming,smoothand durable,effectively sticking tothe soles of dirt and dust,and keepingthe working environment clean.

2.Digital label

Each layer of the sticky pad has adigital label for easy replacement andeasy peeling between each laver

3.Transparent protective layer

There is a transparent non-stickyprotective layer on the fist layer,which is manly used for protection.this layer needs to be turn off before use.

4.Simple to use

The surface layer is contaminated tear offthe layerlight and convenient replacement.and quicklv and effectively eliminate thegeneral range of static electricity.

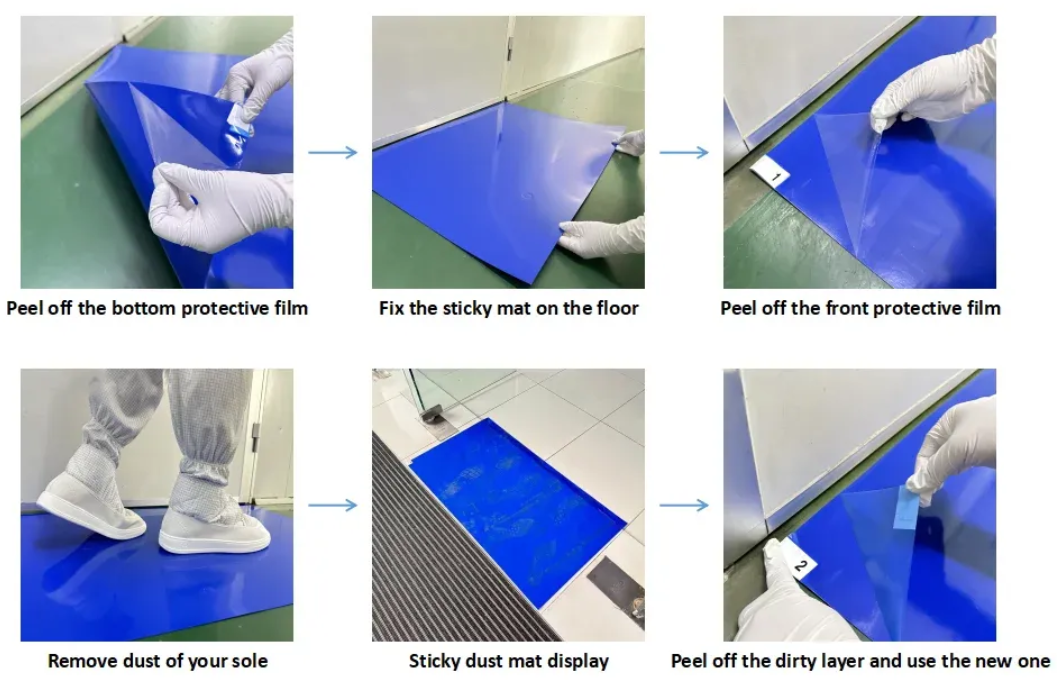

Their primary function is to trap dirt, dust, and other impurities from the shoes or wheels of equipment, preventing these contaminants from spreading further into the controlled environment. Proper installation and placement of these mats play a pivotal role in maximizing their efficacy.

Before embarking on the installation process, it's crucial to prepare the area adequately. Ensure that the floor surface is clean, dry, and free from any debris or contaminants. A thorough cleaning of the floor using appropriate cleaning agents is necessary to ensure optimal adhesion of the sticky mat.Carefully unroll the sticky mat and position it in the desired location. Ensure that the adhesive side of the mat securely attaches to the clean floor surface. Smooth out any air bubbles or wrinkles to guarantee a flat and secure fit. Proper alignment is crucial to prevent any gaps that may allow contaminants to bypass the mat.

1.peel off the bottom protective film

2.fix the sticky mat on the floor

3.peel off the front protective film

4.remove dust of your sole

5.sticky dust mat display

6.peel off the dirty layer and use the new one

Efficient sticky mat installation offers several key benefits that contribute to maintaining a clean and controlled environment. These advantages include:

Reduced risk of cross-contamination

Enhanced cleanliness and hygiene standards

Improved performance and longevity of equipment

Compliance with industry-specific regulations and standards

- MULTIPLE USES -

Adhesive mats are widely used in a variety of industries including: Semiconductor, Biotechnology, Medical Devicorkshop and reception environments (e.g. Mechanic Shop to Reception Desk).

- GREAT FOR USE -

The mats are ideal for a wide range of applications including cleanroom entrances, gowning rooms, laboratories,home, hospitality industry, food prep locations, or work stations that require high levels of contamination control.